Menu

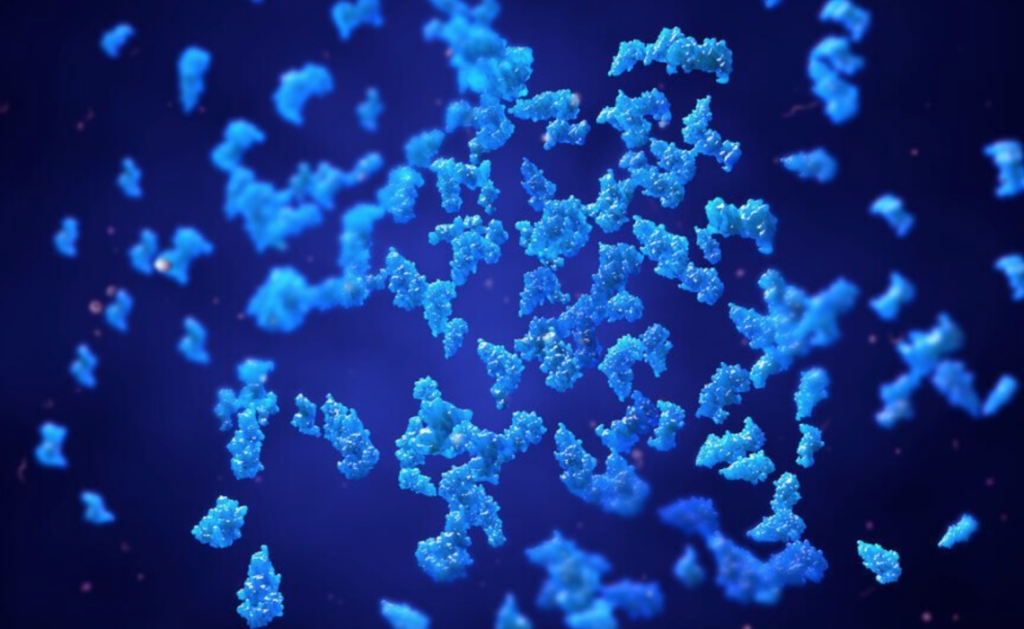

Protein aggregation is the spontaneous clustering or clumping together of protein molecules, resulting in the formation of larger structures called aggregates.

This phenomenon can occur during the manufacturing, storage, or administration of protein-based biologic therapeutics, which are medications derived from biological sources, such as proteins or antibodies.

The effect of protein aggregation on the quality of biologic therapeutics is a significant concern in the pharmaceutical industry. Some key impacts include:

Aggregated proteins may have reduced solubility, which can necessitate lower concentrations of the therapeutic protein. This limitation may impact the maximum dose that can be delivered via certain routes, such as intramuscular (IM) or subcutaneous (SC) injections, potentially requiring intravenous (IV) delivery.

Depending on the nature of the aggregates, changes in solution viscosity can occur. Compact aggregates may decrease viscosity, while extended structures that can entangle with one another may increase viscosity. This can affect the ease of administration, especially in IM or SC delivery.

Irreversible aggregates are considered degradation products. If present in the bloodstream, they can pose risks of immune responses in patients. This can lead to patients developing immunity to the therapeutic protein or, in rare cases, result in autoimmune diseases.

Visible aggregates are often viewed negatively from a marketing perspective. Patients and clinicians typically expect injectable products to be transparent and free from visible particles. The presence of aggregates can raise concerns about the product’s safety and efficacy.

Pfanstiehl’s Technical Sales Scientists can discuss with you to understand your challenges and provide guidance based on experience and literature reviews to help mitigate protein aggregation in biologic therapeutics. Controlling and minimizing aggregation is crucial for maintaining the safety, efficacy, and quality of these medications. Let us help put together some ideas for :

Addition of stabilizers, such as sugars, polyols, or surfactants, can help prevent aggregation by stabilizing the protein structure and reducing intermolecular interactions.

Pfanstiehl HPLE-LMTM Sucrose

Pfanstiehl HPLE-LMTM Trehalose

Pfanstiehl HPLE-LMTM Maltose

Pfanstiehl HPLE-LMTM Mannitol

Amino acids play a key role in reducing protein aggregation in biologics, which is critical for maintaining the stability, efficacy, and safety of therapeutic proteins like monoclonal antibodies or enzymes.

Proper selection of buffer systems can help maintain the protein’s stability and solubility. Maintaining the optimal pH for a particular protein is crucial.

Pfanstiehl HPLE-LMTM TRIS Base

Pfanstiehl HPLE-LMTM Tris HCL

Pfanstiehl HPLE-LMTM Sodium Succinate

For over 100 years, Pfanstiehl has made cGMP Injectable grade excipients, stabilizers, and buffer components that are guaranteed high purity and low endotoxin. Pfanstiehl components are used in the majority of the world’s top selling pharmaceuticals and we continue to grow every year.

Our customers know that Pfanstiehl’s award winning high purity low endotoxin cGMP components will help ensure better consistency from batch to batch and reduce the risk of manufacturing batch failure for your therapeutic.

If you have a protein biologic or vaccine that requires high purity & low Endotoxin excipients, please contact us.