Menu

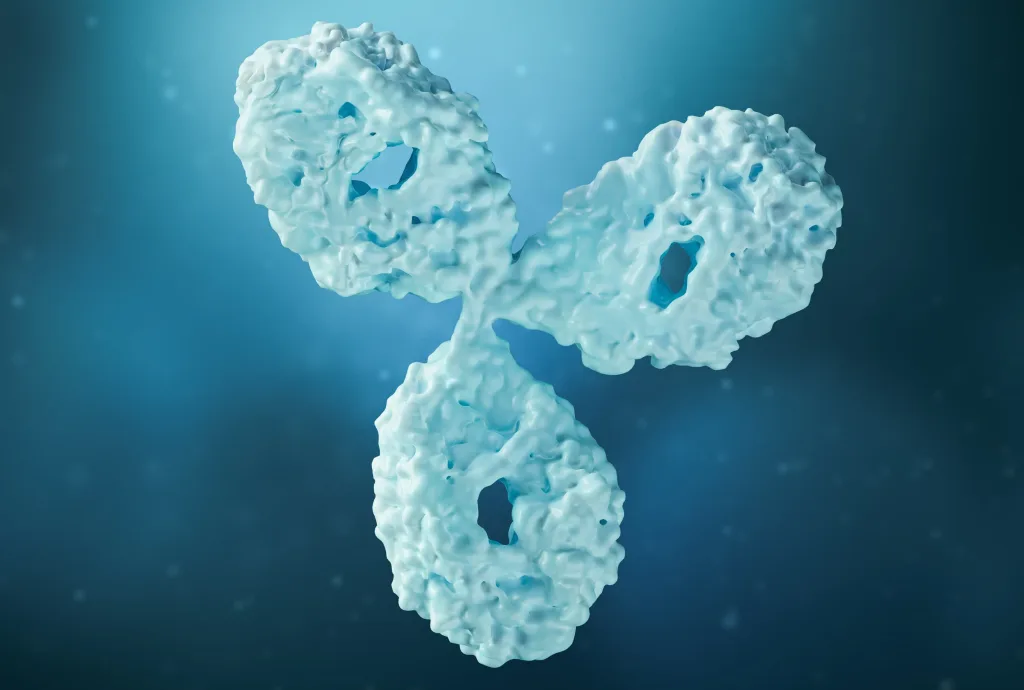

Stabilizing bispecific or trispecific monoclonal antibodies (mAbs) presents several challenges due to their complex structures and the increased likelihood of instability compared to traditional monoclonal antibodies.

Multi-specific mAbs are prone to chemical degradation, such as deamidation, oxidation, and hydrolysis. These processes can alter the function and binding affinity of the antibodies.

They may also be more susceptible to physical instability, such as denaturation and precipitation, especially during manufacturing, storage, and transportation.

The production process is more complex, requiring precise control over conditions to maintain stability. Any variations can result in instability or loss of functionality.

Excipients must be compatible with the mAbs and not interact adversely. This requires thorough screening and testing during formulation development.

The concentration of excipients must be optimized to achieve the desired stability without causing adverse effects.

Excipients should be Generally Recognized As Safe (GRAS) and comply with regulatory standards for pharmaceutical formulations.

Long-term stability studies under various conditions (temperature, humidity, light exposure) are necessary to ensure that the selected excipients provide adequate protection throughout the product’s shelf life.

Stability and shelf life of bispecific or trispecific monoclonal antibodies are significantly influenced by the careful selection of excipients.

These excipients help mitigate the inherent instability challenges posed by the complex structure of multi-specific mAbs, ensuring their efficacy and safety over time

Pfanstiehl’s Technical Sales Scientists can discuss with you to understand your challenges and provide guidance based on experience and literature reviews to reduce the viscosity and stabilize the structure and biologic activity of your complex antibody.

Let us help put together some ideas for:

Incorporating stabilizing agents like sugars or polyols can protect proteins from denaturation and aggregation during storage and handling.

Pfanstiehl HPLE-LMTM Sucrose

Pfanstiehl HPLE-LMTM Trehalose

Pfanstiehl HPLE-LMTM Maltose

Pfanstiehl HPLE-LMTM Mannitol

Incorporating viscosity-reducing excipients like arginine, sodium chloride, or specific amino acids can mitigate viscosity increases while maintaining stability.

Pfanstiehl HPLE-LMTM L-Arginine

Pfanstiehl HPLE-LMTM L-Arginine HCL

Pfanstiehl HPLE-LMTM L-Histidine

Pfanstiehl HPLE-LMTM L-Histidine HCL

Adjusting the buffer system’s pH and composition can enhance solubility and stability, crucial for high concentration formulations.

Pfanstiehl HPLE-LMTM TRIS Base

Pfanstiehl HPLE-LMTM Tris HCL

Pfanstiehl HPLE-LMTM Sodium Succinate

For over 100 years, Pfanstiehl has made cGMP Injectable grade excipients, stabilizers, and buffer components that are guaranteed high purity and low endotoxin. Our components are used in the majority of the world’s top selling biopharmaceuticals and we continue to grow every year.

Our customers know that the combination of Pfanstiehl’s award winning technical support and high purity low endotoxin cGMP components will help ensure better consistency from batch to batch and reduce the risk of manufacturing batch failure for your therapeutic.

If you have a complex antibody or protein biologic requiring an excipient solution, please contact us and we will be happy to discuss how we can work together to make your product as high quality as possible.