Menu

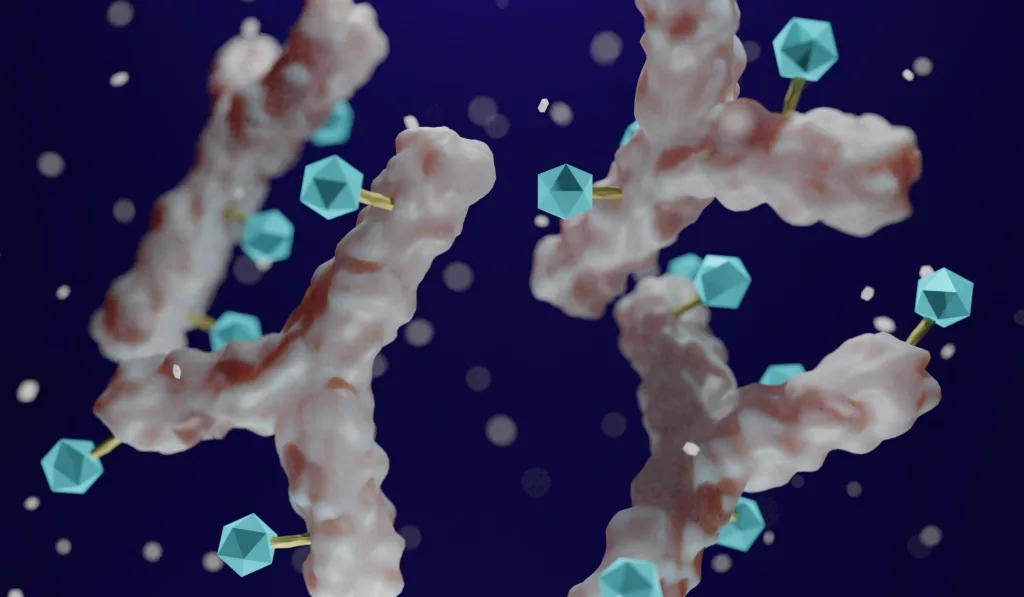

In targeted cancer therapies, Antibody-Drug Conjugates (ADCs) stand as a cutting-edge solution, merging the precision of monoclonal antibodies with the potency of cytotoxic drugs. Central to their success are the linkers connecting the antibody to the drug, a vital component where quality is non-negotiable.

Pfanstiehl’s high-quality Good Manufacturing Practice (GMP) services for ADC linkers ensure the highest standards, supporting both therapeutic success and regulatory compliance for these life-changing treatments.

The linkers in ADCs are the workhorse behind the treatment’s effectiveness, responsible for maintaining the stability and functionality of the entire drug complex. Pfanstiehl’s GMP-manufactured linkers are crafted with exacting precision, ensuring key features like stability, solubility, and controlled reactivity are consistently achieved. This level of control is critical for:

The safety of ADC therapies is paramount, and high-quality GMP manufacturing is essential in mitigating risks. Pfanstiehl’s rigorous GMP protocols guarantee that linkers are produced with unmatched purity and consistency, addressing key safety concerns such as:

ADCs face significant regulatory hurdles, making high-quality GMP manufacturing a non-negotiable aspect of their development. Pfanstiehl’s manufacturing practices provide essential support in navigating this complex landscape:

From clinical development to large-scale commercialization, Pfanstiehl’s GMP manufacturing services are built to support ADC therapies throughout their lifecycle. Benefits include:

High-quality GMP manufacturing is essential for ensuring the therapeutic efficacy, safety, and regulatory success of ADCs. Pfanstiehl is proud to lead the way in delivering the industry’s highest-quality ADC linker solutions, supporting the advancement of innovative and life-saving cancer treatments. Through our commitment to GMP excellence, we provide the foundation for the next generation of ADC therapies, bringing hope to patients and confidence to our partners.