Pfanstiehl D-Mannose Citation Page

Menu

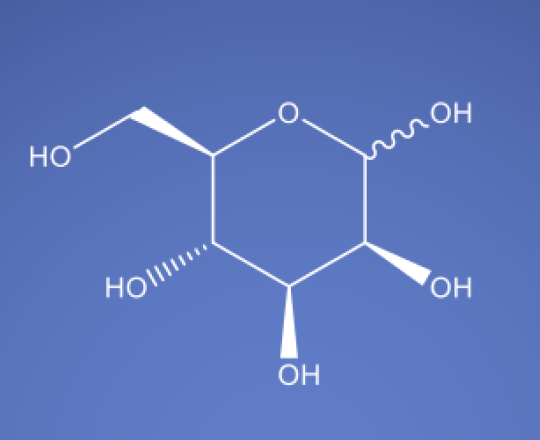

D-Mannose

Molecular Formula

C6H12O6

CAS No

Molecular Weight

Solubility in Water

Boiling Point

Melting Point

Quality Level

Highest – Parenteral Excipient Grade cGMP

Suitable for Injectable Biologic & Vaccine formulation

Suitable for Upstream Protein Production

D-Mannose is a C-2 epimer of glucose and a sugar monomer of the aldohexose series of carbohydrates and is important in human metabolism, particularly in the proper glycosylation of native proteins.

During pharmaceutical protein production, Pfanstiehl High Purity Low Endotoxin Mannose can play a crucial role in optimization and consistency of glycosylation, potency, and yield.

Glycosylation is a post-translational modification process where sugar molecules are attached to proteins. This process is important for the stability, solubility, and biological activity of many therapeutic proteins. Mannose is involved in glycosylation pathways, and its presence can influence the glycosylation patterns of proteins. By adding D-Mannose to the culture medium during protein production, researchers can modulate the glycosylation patterns of therapeutic proteins, ensuring a more consistent and desired profile.

The presence of mannose during protein production can enhance the potency of therapeutic proteins. Glycosylation patterns can affect the pharmacokinetics, stability, and receptor binding of proteins. By manipulating the glycosylation process through the addition of mannose, researchers can potentially improve the therapeutic efficacy of the produced proteins. This is particularly important in the development of biopharmaceuticals where small changes in glycosylation can have a significant impact on the biological activity of the protein.

Mannose supplementation in the culture medium can also contribute to the optimization of protein yield during production. The availability of mannose as a substrate for glycosylation reactions can influence the efficiency of the protein folding and secretion process. This can lead to higher expression levels and improved protein yield, which is essential for cost-effective production of therapeutic proteins.

Maintaining consistency in bioprocessing is critical to produce pharmaceutical proteins. D-Mannose supplementation can contribute to the reproducibility of the production process by providing a controlled environment for glycosylation. This helps in reducing batch-to-batch variability and ensures that therapeutic proteins meet quality standards consistently.

Some approaches involve engineering cell lines to overexpress enzymes involved in mannose metabolism. This allows for greater control over glycosylation patterns. By manipulating the intracellular levels of mannose and other sugar precursors, researchers can fine-tune glycosylation to achieve the desired therapeutic profile.

Pfanstiehl D-Mannose Citation Page

Pfanstiehl’s High Purity, Low Endotoxin, and Low Metals Mannose is manufactured under ICH-Q7 cGMP conditions.

All Pfanstiehl products are made in the USA.

Because of these stringent manufacturing specifications and Pfanstiehl’s quality systems, you can be assured that Pfanstiehl’s Mannose will be of the highest consistency from batch to batch and the safest available for use in your drug product formulation or research application.

D-Mannose

Highest – Parenteral Excipient Grade GMP

Highest Purity

Lowest Endotoxin

Lowest Metals

Lowest Bioburden

In Review

Upstream BioProcessing

Pharmaceutical Process

Biopharma Process

D-Mannose

Highest – Parenteral Excipient Grade GMP

Highest Purity

Lowest Endotoxin

Lowest Metals

Lowest Bioburden

In Review

Upstream BioProcessing

Pharmaceutical Process

Biopharma Process

100g, 1kg, 5kg, 10kg, 25kg, and 50kg